320sqm Hop Siup Kids Indoor Playground in Zielona Góra, Poland - Pokiddo Design and Construction Case

- Share

- publisher

- Leon

- Issue Time

- Jul 7,2025

Summary

This article presents the construction case of Hop Siup Kids Indoor Playground in Zielona Góra, Poland. It details the project from the client's expansion plan to the final completion, including project overview, design concepts, construction processes, and client feedback. Through careful planning and innovative design, a unique indoor playground for children aged 6 - 12 has been created.

Zielona Góra, Poland Hop Siup Kids Indoor Playground 320sqm - Pokiddo Design and Construction Case

1. Project Overview

Project Name: Hop Siup Kids Indoor Playground

Project Address: Zielona Góra, Poland

Project Area: 320sqm

Project Floor Height: 5.2 - 6.6m

Project Features: A diverse range of entertainment facilities suitable for children aged 6 - 12, including a trampoline park, rope playground, flying slide, donut slide, and ninja course.

Opening Date: 2025.12

2. Project Background

The client had been running a small but charming indoor children's playground in the local area. This year, they decided to expand their business. The original playground was targeted at children aged 3 - 6. Therefore, for the new venue, they set their target audience as children aged 6 - 12 from the very beginning.

During the communication process, the client was concerned about how to make the most of the new space and provide a unique experience for the older children. Our team understood their concerns and started a series of in - depth discussions with them from the end of February to mid - May. We conducted multiple design discussions, aiming to meet the client's requirements and create a playground that would attract the target audience.

3. Site Analysis

City Analysis

Zielona Góra is a city in Poland with a growing demand for children's entertainment. There is a significant population of families with children, providing a stable customer base for the project. The local economy is also developing, which means that families have more disposable income to spend on their children's entertainment.

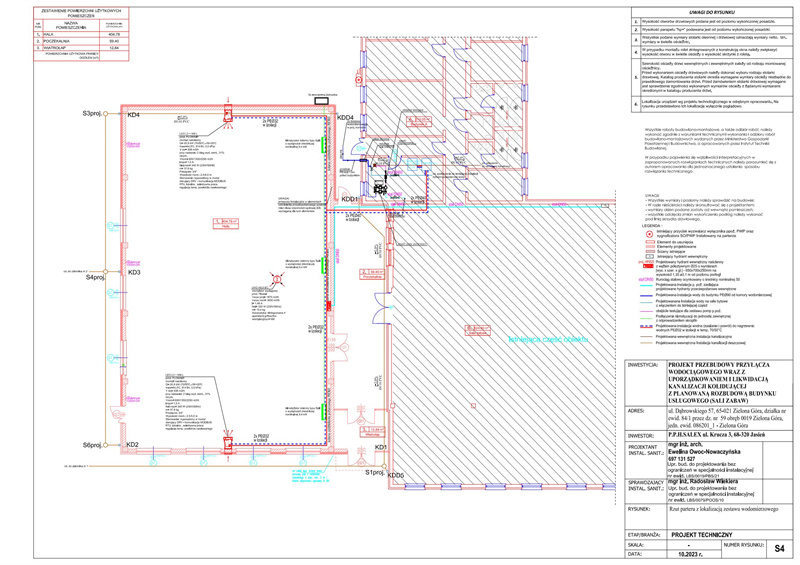

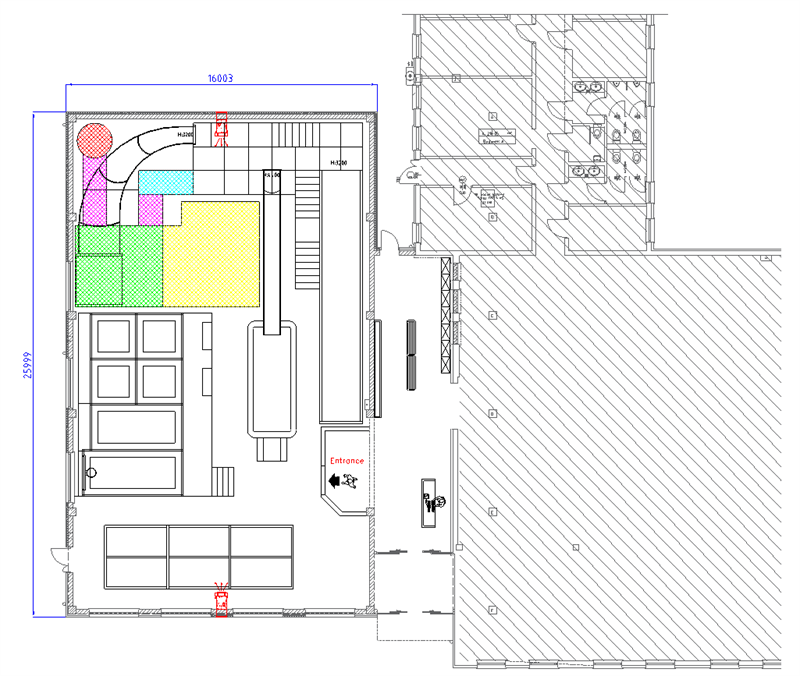

Site Analysis

The site is a rectangular space without any columns, which is very convenient for planning. This advantage allowed us to design a more flexible and efficient layout. We could easily arrange the equipment and create different functional areas according to the needs of the children.

4. Design Concept

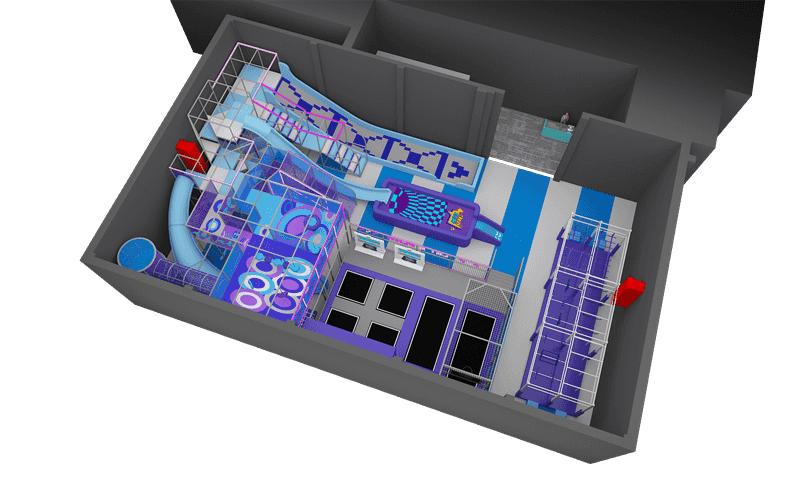

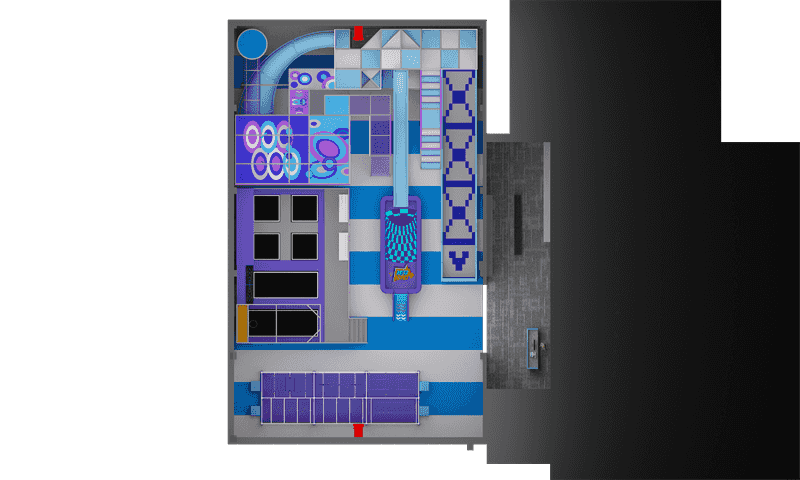

Our design concept was to make the most of the limited space and provide as many rich and classic entertainment projects as possible. We aimed to include all the projects that children love, such as bouncing, sliding, flying, and jumping. Taking advantage of the high ceiling height, we designed a two - layer combination of a rope playground and slides.

We believed that this design would not only provide a thrilling experience for the children but also make full use of the vertical space. The two - layer structure would add more levels of fun and exploration, allowing the children to have a more immersive experience. The client was very impressed with this design idea and gave us full support.

5. Project Planning Introduction

The project was divided into several phases. First, we conducted a detailed site survey and analysis to understand the characteristics of the space. Then, we started the design phase, where we worked closely with the client to finalize the layout and design details. After the design was approved, we entered the equipment procurement phase. We carefully selected the equipment suppliers to ensure the quality and safety of the equipment.

During the planning process, we considered the flow of people and the interaction between different areas. We designed clear paths and rest areas to ensure that the children could move around easily and have a comfortable experience. We also took into account the maintenance and management of the equipment, making sure that it would be easy to clean and repair.

6. Equipment Selection Introduction

We selected a variety of equipment that was suitable for children aged 6 - 12. The trampoline park was equipped with high - quality trampolines that provided a safe and exciting bouncing experience. The rope playground had different levels of difficulty, allowing the children to challenge themselves at their own pace. The flying slide and donut slide added a sense of speed and thrill, while the ninja course provided a test of strength and agility.

All the equipment met international safety standards and was made of durable materials. We also considered the aesthetics of the equipment, making sure that it would fit in with the overall design of the playground. For example, the colors of the equipment were bright and attractive, which would appeal to the children.

7. Project Circulation Introduction

The project circulation was designed to ensure a smooth flow of people. The entrance led directly to a central area, where the children could choose which area they wanted to go to. From the central area, there were clear paths leading to the trampoline park, rope playground, slides, and ninja course. There were also rest areas and viewing areas along the paths, allowing the parents to rest and watch their children play.

We used signs and markings to guide the children and parents, making sure that they could easily find their way around. The circulation design also took into account the safety of the children, avoiding any potential congestion or accidents.

8. Pre Assembly

At our manufacturing facility, we conduct comprehensive trial assemblies for all critical structural components. This essential process allows us to verify dimensional accuracy, ensure perfect fit and alignment, and confirm overall structural integrity before the product leaves our factory. By systematically testing and validating each key element through physical assembly, we proactively identify and resolve any potential issues, guaranteeing that the final product meets our stringent quality standards and performs reliably in its intended application.

9. Delivery and Shipment

Through the expertise of our highly skilled loading specialists, two high cube containers have been packed to their maximum capacity, achieving nearly 100% utilization of the available internal space. This efficient and strategic arrangement ensures optimal shipment consolidation, minimizes wasted space, and demonstrates our commitment to cost-effective and secure logistics solutions for your order.

Pokiddo: Your Global Partner in Playground Innovation Since 2017, we've empowered 800+ indoor entertainment centers across 126 countries. Our dual expertise as equipment engineers and park operators ensures solutions that maximize lifetime value.